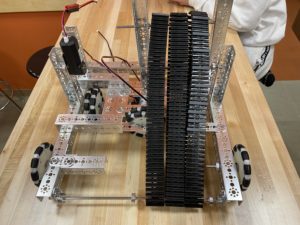

Over the past two weeks many changes and improvements have been made to the robot. The ring shooter outtake is working very well and has had the finishing improvements and tweaks put on it over the last two weeks. Improvements include moving the motor mounts to the far right, flipping the wheels so that they would sit lower on the feeding mechanism, and adjusting the height of the ring feeder mechanism. We also improved the robot itself by adding a third motorized wheel to the drive train of the robot, giving the robot more mobility. The conveyor belt, on the other hand, is a different story. We did improve the conveyor belt by replacing the 1 diameter gears with 3 diameter gears, linking Tertix 1.5 conveyor pieces to build the belt itself, and adding grips to the conveyor pieces in order to hold the rings in place. This came with many problems though as when we tested the tread system, we found that the treads were bouncing causing the robot to lose possession of the rings and that the tread system was too steep to move the rings up the robot effectively. This, however, is a blessing in disguise as now we know that we need a new system that will be faster and more effective. We can learn from are mistakes and see what went wrong with the conveyor belt system and how to avoid these issues in the future.

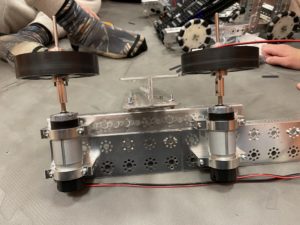

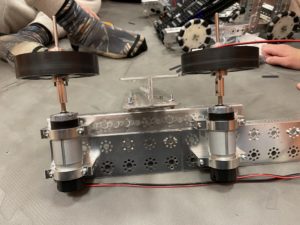

Eli and Kyle add a third motorized wheel to the drive train of the robot.

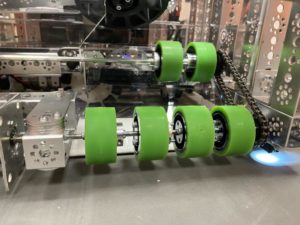

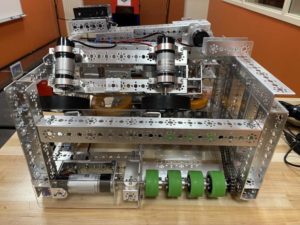

The new and improved ring shooter design.

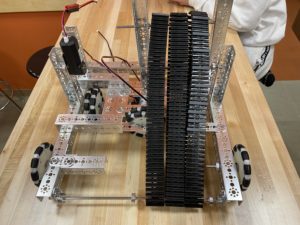

A look at the conveyor belt system used to intake the rings (without the grips on the treads).